Manufacturers of world class Diamond and CBN Grinding Wheels in India Our more than 40 years of single-handed experience duly maintaining the continuity of manufacturing & developing the impregnated super abrasives products which has given us an edge in delivering the Products & Quality, which you will rarely find in the world today. Tailor-Made to suite your application.

About Us

Mr. Harish S. Patel, after completing his BE (Mech.) from BVM, Vallabh Vidhyanagar, India, went to USA to pursue his MS (Manufacturing) from IIT, Chicago.

He is working in manufacturing of Diamond Wheels since 1964. He got an opportunity to work in USA with different Companies for about 10 years and then started Hindustan Products in 1972 and is serving Indian Industry as well as Exporting to Countries like USA.

Since then, the company has strived to give the best quality Diamond/CBN Wheels available in market catering to individual needs of cutting/ drilling/ grinding/ polishing of various industries like carbide tool manufacturers, High Speed Cutters, Stainless Steel products, Silicon Chips, Glass Industry, Diamond Industry, Granamite Tiles manufacturing, Stone Cutting, etc.

Our Research over the past years have developed various Bonds and Products for Diamond and CBN wheels applications which are not easily available in the market and thus keeping in pace with present day needs and industry.

The experience of more than 40 years has helped many industries with their special requirements of tooling, reducing manufacturing cost, prolong life as well as increasing cost-efficiency.

Products

- Wheels in continuous rim in Metal and Resin Bond

- Minimum Thickness = 0.3 mm. in smaller sizes.

- Maximum Diameter in Metal Bond = 300 mm.

- Maximum Diameter in Resin Bond = 550 mm.

- 250 mm Diameter in 1 mm thickness

- 300 mm Diameter in 1.5 mm thickness

- Mirror Finish Wheel for Grinding : One can achieve 3 micro - inch finish by grinding with 600 grade wheel.

- Centre less Grinding Wheel : Sizes upto 500 diameter x 150 thickness gives perfect size and mirror finish in one pass.

- Form Wheels, Cup Wheels, Dish Wheels for different uses.

- Mounted wheels/points with spindle in metal bond / Resin Bond grinding carbide.

- Diamond Lapping Compound

- Hand Laps.

- CBN Wheel :-

- For grinding High Speed steel without discoloring the work-piece.

- For notching a groove of 0.4 mm. wide.

- High Speed Cutter Teeth Grinding Wheel for plunge cut.

- For grinding Stainless Steel knife and blade etc.

- Mounted wheels/points with spindle in metal bond / Resin Bond High Speed steel and super alloys.

- Cutters in different sizes.

- Molding Wheels of different shapes.

- Ceramic Segmented Rollers for Roller Finishing.

- F-7 Grade Glass Grinding Wheels for scratch free finish, F-9 Grade for transparent finish and trepanning tool of wall thickness as thin as 1 mm in addition to All different shape and sizes of Glass Grinding Wheels

- Solid Body Gold Brand Carbide/Glass Grinding Wheels provides strength against crack and works on small machines as Higher Moment of Inertia.

- Mini-Vee Wheels in Diameter of 125mm, 140mm, 150mm etc.rks on small machines as Higher Moment of Inertia.

- Self-Centering wheels for different Auto Edger Machines like Takubomatic, Grand Seiko, Weco, Essilor.

- Curve-Generators in different sizes. Available in Convex and Concave shapes.

- Supra Wheels in diameter 25 and 30 mm

- Trepanning Tools as per different requirements.

- Glass Cutters in Diameter 75, 100, 125, 150, 175, 200, 250, 300 mm.

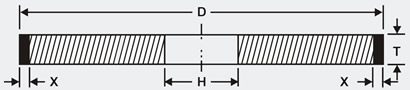

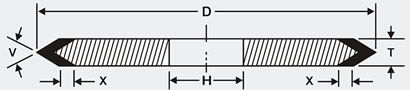

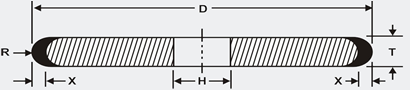

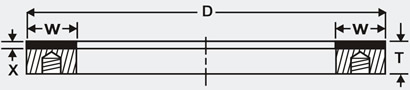

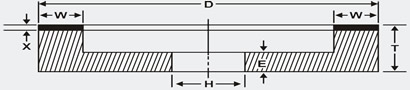

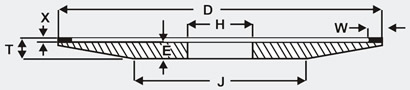

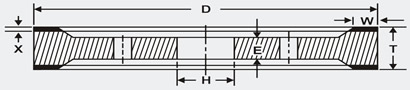

| Type | Drawing |

|---|---|

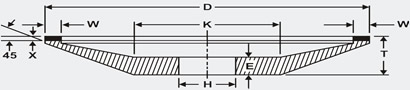

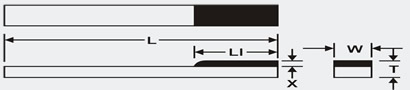

| 1A1 |  |

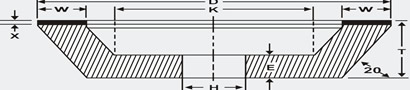

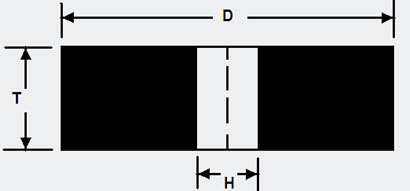

| 1EE1 |  |

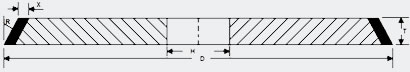

| 1FF1 |  |

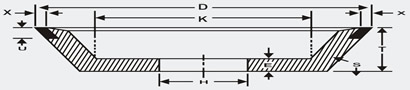

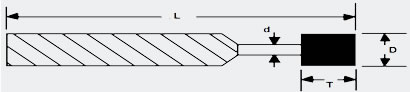

| 2A2T |  |

| 6A2 |  |

| 6A9 |  |

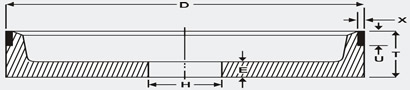

| Type | Drawing |

|---|---|

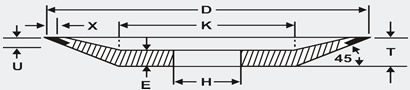

| 11A2 |  |

| 11V9 |  |

| 12A2 |  |

| 12V9 |  |

| 15V9 |  |

| HH1 |  |

| Type | Drawing |

|---|---|

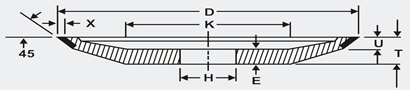

| 1A1R |  |

| 1A8 |  |

| 1V1 |  |

| WS |  |

| 4A2 |  |

| 9A3H |  |

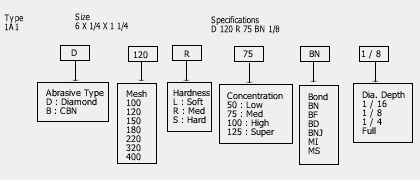

How To Order

Specify where it applies :

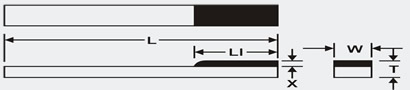

- Type of the wheel/Drawing

- Diameter (D) X Thickness (T) X Hole (H)

- Face Width/Height (W/U)

- Radius/Angle (R/V)

For Example:

SELECTION GUIDELINES FOR SPECIFICATIONS

- ABRASIVE : Diamond : Carbide Grinding

- CBN: Molybdenum and Tungsten type High Speed steels and other super alloys grinding

- GRIT : Use coarsest grit commensurate with finish required from the table below.

| Grit (Mesh) | Finish (Micro inch) | Finish (Micron) |

|---|---|---|

- HARDNESS:

- CONCENTRATION:

/>

/>-

BOND:

- DIAMOND DEPTH :